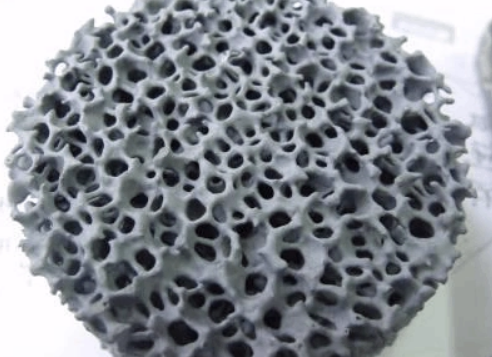

The ceramic foam has a excellent three-dimensional network structure and magnesium oxide additive is needed in the production. Magnesium oxide has a excellent adsorption and filtration effect on impurities in foamed ceramics, which can filter various inclusions and impurities in magnesium and magnesium alloy molten liquid, improve the inherent quality of castings and reduce defects, and has the advantages of tiny heat capacity, modest resistance and large filtration capacity, so it is extremely suitable for the filtration of magnesium and magnesium alloy molten liquid.

Magnesia foam ceramic foam filter can be divided into bonded type and sintered type: the former adhesive foam ceramic can not be used for magnesium liquid filtration; the latter is made of superior purity magnesium oxide powder sintered and fused together by holding at elevated temperature. It is required that this product needs magnesium oxide particle size uniform, low hydration rate, with certain sintering activity.